REF F421301

- Currently unavailable

TOYOBO

REF F421301

2 sizes are available: A4 (21x29,7cm) et A3 (29,7x42cm)

Technical information:

Base: Steel

Etymologically, the term "photo" means light, "poly" means several, and "mer" means unit.

A photopolymer plate consists of a set of independent particles that are sensitive to ultraviolet light.

These particles are sensitive in the sense that they bind together to form a hard material after being exposed to UV light.

Water-soluble, the unexposed particles, which are therefore not bonded, are dissolved away.

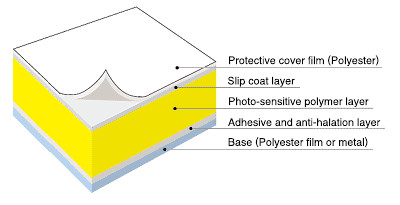

Plate structure

A protective film to protect against scratches and dust

A steel base (non-retractable)

Development

Toyobo Printight plates are developed using tap water.

Drying

Post-exposure

The plate is finalized with post-exposure: 5 to 15 minutes under UV light (depending on the power of the source) permanently hardens the polymer.

Specific References

You might also like

Cranfield Traditional litho ink